EnergyArmour

Custom Covers

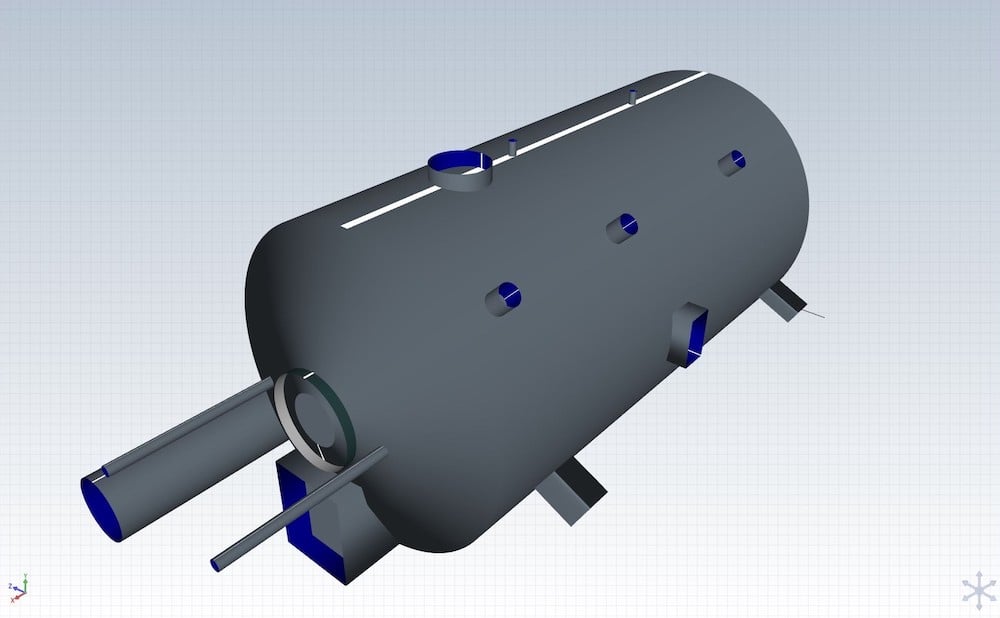

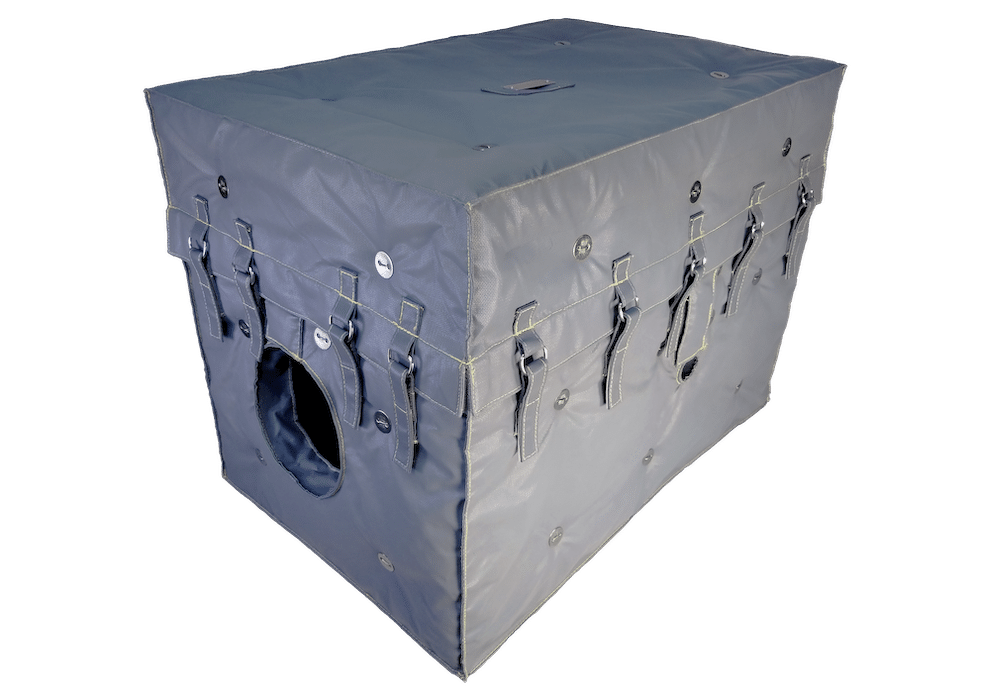

EnergyArmour specializes in custom cover fabrication for all types of equipment configurations, piping, specialty items, and specification requirements. EnergyArmour Custom Covers can be used in a variety of applications including:

Valves

Strainers

Pumps

Compressors

Turbines

Exhaust Systems

Equipment

Specialties

Instruments

…and MORE!

Please contact us for a consultation and quotation for those unusual items requiring custom measurement and fabrication.

Cover Classes

Custom removable covers are constructed for heat conservation, personnel protection and freeze protection. Application temperatures can vary greatly. We breakdown our cover into three classes:

LT Covers (Low Temperature)

This class of Cover has an upper temperature limit of 500F. The shell is made to resist and shed water and the joints are constructed with flaps made of the shell material to help prevent liquids from infiltrating the cover. Fiberglass mat is used as the insulation material. These covers are very easy to install by means of the integral hook and loop for the flaps on longitudinal joints and draw ropes to cinch down covers circumferentially to limit heat loss/gain. All seams are typically sewn to create an insulation cover with a great look. These covers are suitable for personnel protection, heat conservation and freeze protection.

MT Covers (Medium Temperature)

This class of cover has an upper temperature limit of 800F. The outer shell is made to resist and shed water. The inner surface of the shell (hot side) is constructed of a fabric to meet the temperature demands. Fiberglass mat is used as the insulation material. Like the LT covers, flaps are provided to help prevent liquids from infiltrating the cover. MT covers are installed by means of lacing hooks and wire to secure flaps on longitudinal joints and to cinch down the blanket circumferentially limiting heat loss. All seams are typically sewn to create an insulation cover with a great look. These covers are primary used for heat conservation and personnel protection.

HT Covers (High Temperature)

This class of cover has an upper temperature limit of 1200F. The outer shell is made to resist and shed water. The inner surface of the shell (hot side) is constructed of stainless-steel wire mesh to withstand the high temperature. The filler is constructed of two parts: needle-mat insulation (hot side) and additional layers, when required will be fiberglass mat (cold side). HT covers are installed by means of lacing hooks and wire to secure flaps on longitudinal joints and to cinch down the blanket circumferentially limiting heat loss. All seams are sewn and hog-ringed only where necessary. These covers are primary used for heat conservation and personnel protection.

UT Covers (Ultra-High Temperature)

This class of covers (>1200F) are available on a custom design basis. Please contact the EnergyArmour Team to advise your design.

Custom Fabrication

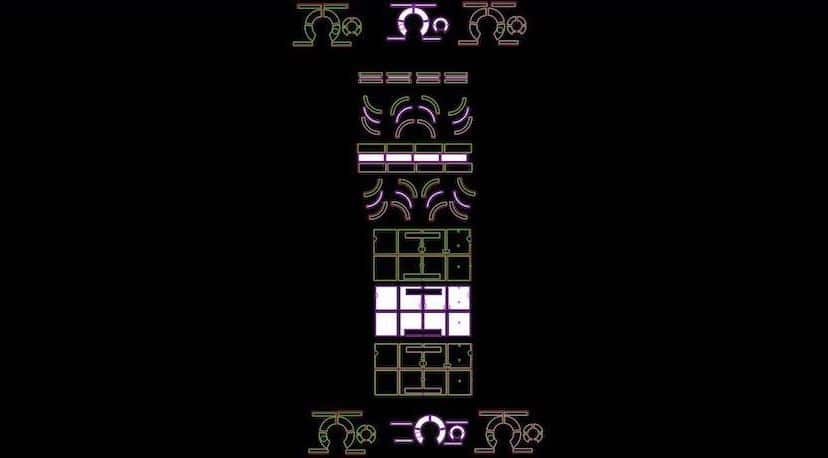

You are welcome to send us detailed drawings for fabrication (preferably CAD), or if you prefer we’ll send a field engineer to your site to accurately measure your application. Field measurements are transferred electronically to our fabrication facility to the designer so fabrication can begin even before the engineer returns. This expedites blanket turnaround time.

Design

EnergyArmour specializes in custom cover fabrication for all types of pipe fittings, duct and equipment configurations using CAD and sophisticated 3-D and linear software to accurately design all our coverts. Covers are efficiently and accurately cut using automated table cutting technology.